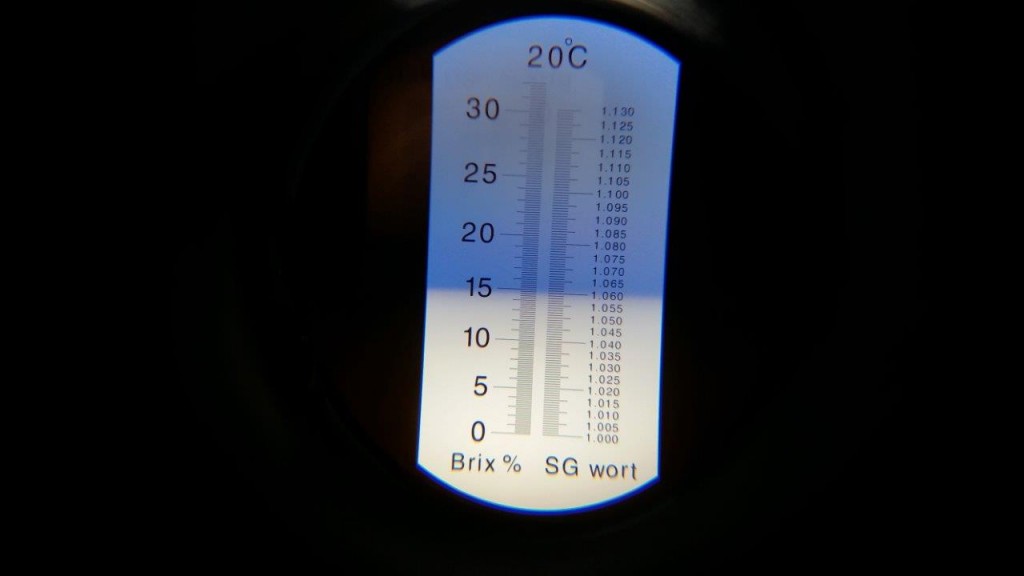

Wow I haven’t posted for a while! I have been very busy remodelling our new house which is where the Chinook hops were grown just this last summer. I have heard a few times not to use the first year hops but, “hey, why not?” About a month ago I brewed up a smash beer with help from a friend. We will call him the ‘Master Stirrer’. What is a smash beer you ask? SMASH stands for Single Mash and Single Hop. And that is exactly what I made, 12 pounds of Belgium Pale Malt and 4 ounces of Chinook whole hops from my back yard. Brew day went well with only a little spilled wert.

This is the finished beer just before racking to the new sanke keg. Another friend borrowed me a keg and his Co2 bottle to give it a try. I filled up the keg and pressurized to 12 psi and let it sit in the garage for a few days. After three days or so I had to try it, I filled a glass about half full and held it up to the light. It was the clearest beer I have ever made! I’m not sure if it was the smash approach or the keg that made it so clear? The pale ale was not quite fully carbonated but it still tasted awesome. There was no corn sugar after taste like there is when bottling. I can’t wait to try this method again. Now I need to pick up a keg system!